The 5-Minute Rule for Motorcycle Parts New Zealand Specialists

Getting The Motorcycle Parts New Zealand Specialists To Work

Table of ContentsSome Ideas on Motorcycle Parts New Zealand Specialists You Need To KnowWhat Does Motorcycle Parts New Zealand Specialists Mean?Some Known Incorrect Statements About Motorcycle Parts New Zealand Specialists Motorcycle Parts New Zealand Specialists Fundamentals ExplainedIndicators on Motorcycle Parts New Zealand Specialists You Should KnowThe 4-Minute Rule for Motorcycle Parts New Zealand SpecialistsAll About Motorcycle Parts New Zealand SpecialistsThe Ultimate Guide To Motorcycle Parts New Zealand Specialists

Reach out to one of our specialists today.CNC machining technology is swiftly becoming the focal point of various manufacturing procedures around the world as a straight result of its several benefits over other methods. Furthermore, the markets that produce motorbikes have gotten on board with this fad. One of the most innovative business are now developing their engine parts and wheels utilizing machining strategies originally created for motorcycle components.

You may be questioning why we make use of. Now that we have your attention allow us clarify the reasoning behind this contemporary advancement in the motorbike manufacturing industry.

Motorcycle Parts New Zealand Specialists - An Overview

In addition, you have full control over the appearance of the parts, even down to the minute details. Occasionally, motorcyclists might choose to spruce up their ride by setting up aftermarket parts or modifying the bike's makeover.

The Definitive Guide to Motorcycle Parts New Zealand Specialists

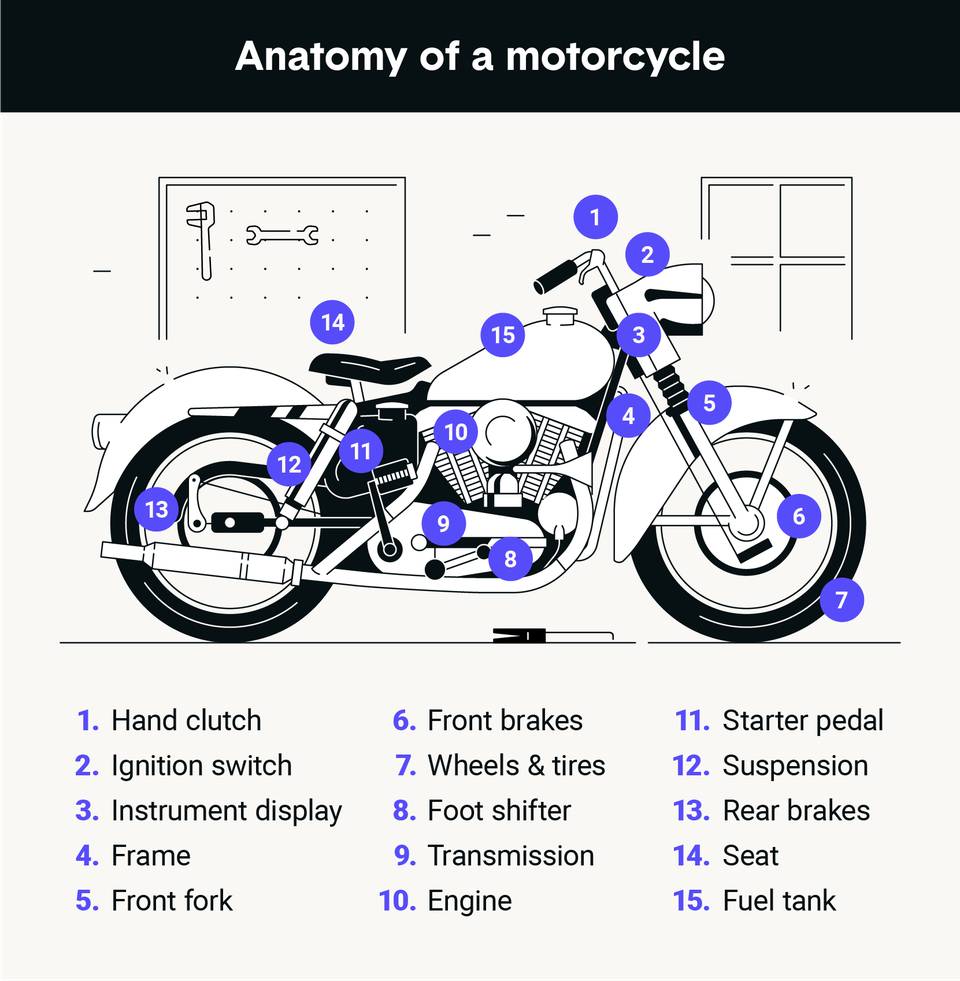

CNC machining may be used to make nearly all of a motorbike's steel and plastic elements. To continue, we'll discuss several machined parts for bikes. In comparison to those on cars, wheels on motorbikes have a tendency to be a lot more evident. As a result, the bike's appearances may be enhanced with the appropriate personalization of these wheels.

Milling procedures are utilized to obtain the preferred degree of wheel personalization. Another facet of the motorcycle that may be customized is the tires.

Motorcycle Parts New Zealand Specialists Can Be Fun For Everyone

When it involves a car (or a motorcycle), one of the most important component is the engine. Several people point to it as the "heart" of the automobile. On the other hand, the camshaft, the cyndrical tube head, and the pistons have a tendency to be elaborate and need styles with a high level of accuracy.

Usage only top notch items, nonetheless, because these lights are important for the security of motorcyclists and various other drivers or people on the road, especially at evening. Motorbike fronts lights have three major parts: the light bulb, or light source, the lens, and the real estate.

Milling procedures with a flawless finish would lead to the lenses having a reflective high quality that is comparable to that of a mirror. The cover, on the other hand, is not composed of breakable products; instead, it is created out of hard polymers that can be machined into more intricate patterns.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking About

They typically have fancy geometries with a riches of min information. Bike makers commonly cast these components, but only for the manufacturing of bespoke parts. CNC machining is the method of option when producing unique items. Machining on 5 axes in today's globe is the ways through which any type of design form may be recognized.

Select Runsom for your tailored motorbike components! We have the capacity to produce complex and elegant components making your motorbike unparalleled.

Below are a couple of examples of steels usually used in motorcycle element machining. Aluminum is the primary material used by companies specializing in producing custom motorbike components to develop many of these parts - Motorcycle Parts New Zealand Specialists.

Zinc refers to one more steel that is extremely light in weight and has great machining qualities because of its high mechanical toughness. This product may be formed into almost any kind of shape and maintains its measurements well. Also mission-critical elements that require a high click for info level of precision may gain from their use.

The Only Guide for Motorcycle Parts New Zealand Specialists

One more metal that sees hefty use in the manufacturing of CNC-customized parts is magnesium. It is amongst the lightest steels that are currently obtainable and has exceptional machinability functions and strength commensurate with its low weight. Among the downsides of magnesium is that its dirt might conveniently catch fire.

Their most typical usage in generating numerous bike components is bolts, such as screws and bolts. Their low vulnerability to oxidation and rust makes them perfect for this usage.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing

It appears that CNC turning and grating are the foundational processes. Nonetheless, alternative techniques exist, such as exploration. Allow's check out several of these machining methods in depth. The CNC turning method is considered a subtractive production approach. In enhancement, it calls for keeping bars of product, usually plastic or steel, in setting and after that turning a cutting device to eliminate areas of the material as the material is transformed.

These techniques are equally essential and produce parts with high accuracy and regular top quality. They are respectively: grinding, laser cutting, and drilling. The term "surface coating" refers to post-processes after the initial machining phase. Motorcycle Parts New Zealand Specialists. The procedures help improve the total high quality of the machined bike components. Below are the short introduction, pros and cons of five surface area treatment techniques.

What Does Motorcycle Parts New Zealand Specialists Mean?